Development of Reversible Solid Oxide Cells with Single Anode and Cathode Materials by Utilizing Nanocatalytic Growth Technology - Published in 'Small', an international academic journal in the field of materials

- 글번호

- 400013

- 작성일

- 2025-01-13

- 수정일

- 2025-01-13

- 작성자

- 홍보팀 (032-835-9490)

- 조회수

- 72

A joint research team led by Professor Myung Jae-ha of Incheon National University's Department of Materials Science and Engineering and Professor Lee Kang-taek of the Department of Mechanical Engineering at the Korea Advanced Institute of Science and Technology (KAIST) developed a high-performance nanostructure electrode material that can be applied as both an anode and a cathode of fuel cells through the development of perovskite oxide-based cobalt-iron alloy nanoparticle control technology.

Reversible Solid Oxide Cells (RSOCs) are systems that combine fuel cells that generate electricity from chemical energy and electrolytic cells that generate fuel using electrical energy. Since both electricity generation and fuel production are possible depending on the situation, they are used as energy conversion devices that can compensate for the gap in power demand and supply due to the power generation volatility of renewable energy affected by weather.

However, the electrode materials of existing fuel cells and electrolytic cells have various fuel environments of each cathode and anode and each required electrochemical reaction, so a specialization study suitable for each electrode was conducted separately.

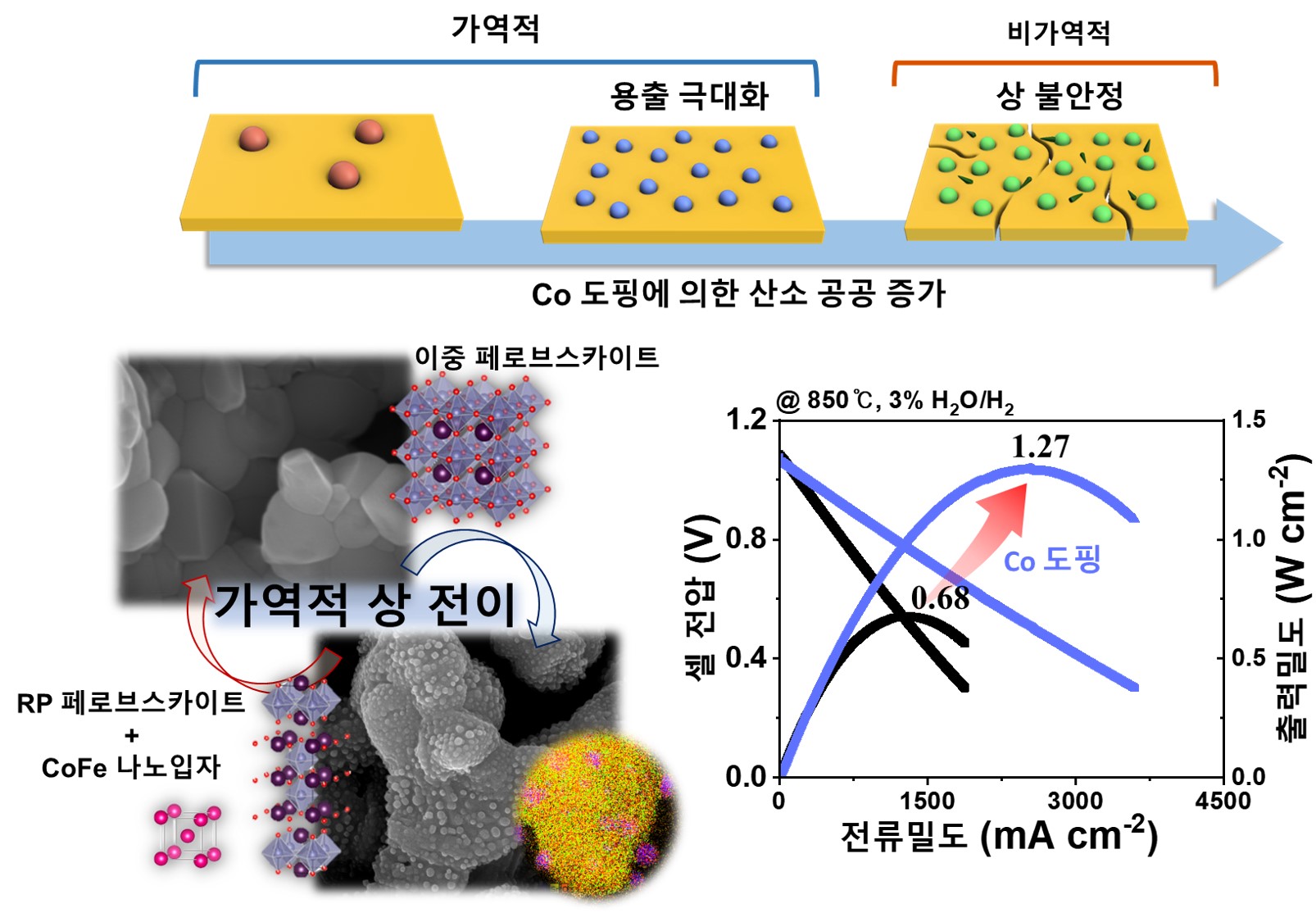

The elution technology is a technology that grows a metal doped on the surface of a perovskite oxide material into a fixed nanocatalyst. Elution can effectively improve the electrochemical activity of the material in an operating environment without a separate catalyst application process. The elution nanocatalyst is a socket structure fixed to the oxide support and exhibits a uniform particle distribution, so it shows high resistance to high-temperature agglomeration and carbon deposition.

This joint research team developed a perovskite oxide-based high-performance nanostructure electrode material using elution technology. The developed elution material showed a trade-off that the growth of the eluted nanoparticles was maximized as the amount of cobalt doping increased, while the stability of the parent image decreased at the same time. By deriving the optimal amount of cobalt doping in the material, the performance of the material could be optimized by securing both the growth of the nanoparticles and the stability of the parent image.

Since this material can be used for both an anode and a cathode, it is evaluated to have a great impact on the fuel cell industry as it can innovatively save the price and process cost of the material. In addition, the reversible solid oxide battery composed of a single symmetrical electrode material developed can directly use various fuels (CO, H2O, H2, CO2), and the maximum power density was 1.27 W cm-2 at 850°C in hydrogen fuel cell mode and the current density was 2.33 A in water electrolysis cell mode at 800°C. In particular, this electrode operated stably without deterioration even in 700 hours of continuous driving that integrated fuel cells and water electrolysis cells, showing high durability even in reversible cycle driving.

The developed material can be applied not only to fuel cells but also to various energy conversion systems such as batteries and carbon dioxide conversion catalysts, which can significantly improve the system's lifespan and performance. Additionally, the research team's material optimization methodology can be used to improve performance in various nanostructured electrode and catalyst studies as it can be applied to the development of other materials.

This research has important application potential in the field of energy conversion and power supply, and in particular, will make important progress in the commercialization of eco-friendly energy conversion devices for carbon neutrality. Through this, it is expected to contribute to the development of future energy systems and the realization of a sustainable society.

Meanwhile, the study was conducted jointly by Professor Myung Jae-ha of Incheon National University and Professor Lee Kang-taek of KAIST, and Jeon Hye-jin (a master's student at Incheon National University), Kim Yo-han (a master's student at Incheon National University), and Kim Hyung-geun (a master's student at KAIST) participated as the first authors. It was conducted with the support of the Korea Research Foundation (Excellent Research, Global Basic Research Lab) with the funding of the Ministry of Science and ICT, and was recently published in the International Journal of Materials (Small, IF=13.0).